Fresh water maker, also known as reverse osmosis unit is a desalination process by removing dissolved salts from seawater under high applied pressure through a semi-permeable membrane. The dissolved salts will be retained on the pressurized side of membrane, which is known as ‘brine’ or ‘reject’. The pure solvent is allowed to pass to the other side, which is known as ‘fresh water’. This reverse osmosis process is applicable for salinity range from 50 – 45,000ppm at 25°C. Fresh water maker is usually designed to treat seawater to meet the outlet requirement of total dissolved solids of 500ppm.

Fresh water maker consists of:

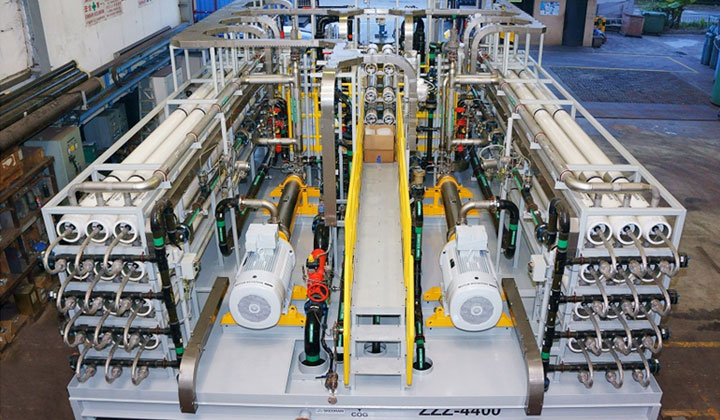

Fresh water maker has advantages of compact footprint and lower CAPEX in terms of power consumption and maintenances. It can be designed in modular form in order to fit into engine room (safe zone area) or topside (hazardous zone area) for ease of installation.

Our design of fresh water maker meets offshore requirements by using robust components, e.g. high pressure pump complied with API-610 standard, ASME certified FRP membrane housing, offshore corrosion resistant paint system and explosion-proof certified electrical and instrumentation components. Our fresh water maker is certified by marine classification society such as ABS, Det Norske Veritas Germanischer Lloyd (DNV GL) and Bureau Veritas (BV)

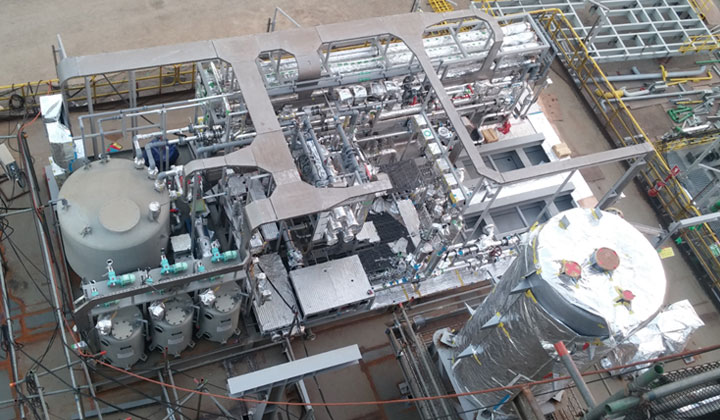

Our systems can be installed in locations where a continuous supply of seawater, river water or ground water is available.

Power Plants, Oil & Gas, Offshore